Description

Needle Valve Specification

|

Materials |

CS, SS, Monel, Hastalloy, Duplex and High Nickel alloys |

|

Orifice |

4.0mm(0.156in)、6.4mm(0.25in),11.1mm(0.437in) |

|

Flow Patterns |

Straight, angle patterns |

|

Design |

Forged Body with Inline/Straight or Angle Pattern, Integral Bonnet Design |

|

Packing |

PTFE,PEEK,PCTFE |

|

End Connection |

Male and Female NPT, BSPT,BSPP,SAE, Socket Weld (SW) or Dual Ferrule Tube Connections, Female to Male, Female to Female, Male to Male |

|

Working Pressure |

Up to 6000 PSIG Needle Valves are also available that can handle higher pressure |

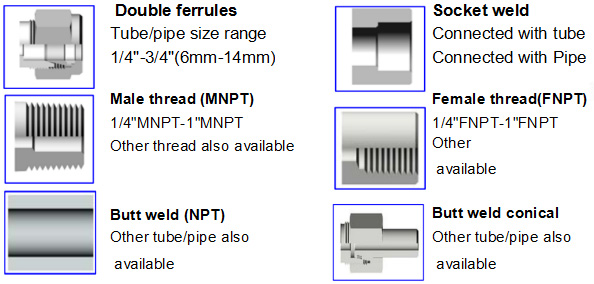

Connection Type:

Needle Gauge Valve Application

Petrochemicals

Biofuels

Textiles

Sugar

Wastewater treatment

Food

Chemicals

Pharmaceutical

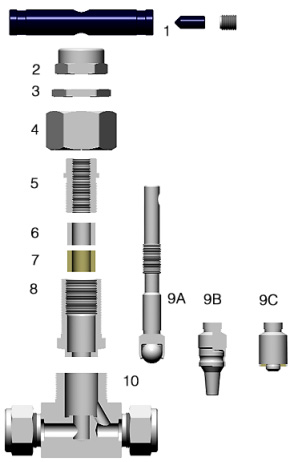

Construction of Needle Valve

| Component | Valve Body Materials | ||

| 316 | C-276 | Alloy 400 | |

| 1 Bar handle | Anodized aluminum | ||

| 2 Packing nut | 316 | C-276 | Alloy 400 |

| 3 Panel nut | 316 | C-276 | Alloy 400 |

| 4 Union nut | 316 | C-276 | Alloy 400 |

| 5 Packing Gland | 316 | C-276 | Alloy 400 |

| 6 Packing Gland | 316 | C-276 | Alloy 400 |

| 7 Packing | PTFE/Soft Graphite | ||

| 8 Lower gland | 316 | C-276 | Alloy 400 |

| 9A Ball stem | 316 | C-276 | Alloy 400 |

| 9B Regulating stem | 316 | C-276 | Alloy 400 |

| 9C Soft-seat stem | 316 | C-276 | Alloy 400 |

| 10 Body | 316 | C-276 | Alloy 400 |

Needle Valve Dimension standards

| End Connections | Size |

Dimensions, in. (mm) |

|||||||||||||||

| Inlet/Outlet | A | B | B1 | B2 | C | D1 | D2 | E1 | E2 | F | G | H | HL | J | |||

| Orifice (4.0mm) | |||||||||||||||||

|

Female

NPT

|

1/8 in | 50.8 | 25.4 | 22.6 | 25.4 | 32.3 | 27.7 | 32.5 | 9.7 | 9.7 | 44.4 | 15.1 | 77.2 | 82.0 | 7.1 | ||

| 1/4 in | 52.3 | 26.2 | 22.6 | 25.4 | 32.3 | 32.5 | 9.9 | 82.0 | |||||||||

|

Male

NPT

|

1/4 in | 50.8 | 25.4 | 25.4 | 25.4 | 35.1 | 27.7 | 9.7 | 77.2 | ||||||||

|

Hi-Tek (MM) tube fittings |

1/4 in | 51.6 | 26.2 | 22.6 | 25.4 | 32.3 | 32.5 | 9.9 | 82.0 | ||||||||

| Hi-Tek (MM) Tube fittings | 1/4 in | 61.0 | 30.5 | 29.5 | 37.6 | 39.1 | 27.7 | 9.7 | 77.2 | ||||||||

| 6mm | 61.0 | 30.5 | 29.5 | 37.6 | 39.1 | 27.7 | 9.7 | 77.2 | |||||||||

| 8mm | 61.0 | 30.5 | 29.5 | 30.2 | 31.8 | 27.7 | 9.7 | 77.2 | |||||||||

| Tube Butt weld | 1/4 in | 46.2 | 23.1 | 22.4 | 30.2 | 31.8 | 27.7 | 9.7 | 77.2 | ||||||||

| Out VCO | 1/4 in | 52.3 | 26.2 | 22.4 | 30.2 | 31.8 | 27.7 | 9.7 | 77.2 | ||||||||

| Out VCR | 1/4 in | 52.3 | 26.2 | 22.4 | 30.2 | 31.8 | 27.7 | 9.7 | 77.2 | ||||||||

| End Connections | Size |

Dimensions, in. (mm) |

|||||||||||||||

| Inlet/Outlet | A | B | B1 | B2 | C | D1 | D2 | E1 | E2 | F | G | H | HL | J | |||

| Orifice (4.8mm) | |||||||||||||||||

| Female NPT | 1/4 in | 57.2 | 28.4 | 25.4 | 28.4 | 38.1 | 37.3 | 12.7 | 12.7 | 63.5 | 19.8 | 94.0 | 97.0 | ||||

| 3/8 in | 57.2 | 28.4 | 25.4 | 28.4 | 38.1 | 37.3 | 94.0 | 97.0 | |||||||||

| Hi-Tek (MM) tube fittings | 3/8 in | 71.9 | 35.8 | 32.8 | 42.2 | 45.5 | 31.0 | 94.0 | 90.7 | ||||||||

| 1/2 in | 77.2 | 38.6 | 35.6 | 41.9 | 48.3 | 34.0 | 94.0 | 94.0 | |||||||||

| 10mm | 72.4 | 36.1 | 33.0 | 39.4 | 45.7 | 34.3 | 93.7 | 94.2 | |||||||||

| 12mm | 77.2 | 38.6 | 35.6 | 41.9 | 48.3 | 34.0 | 94.0 | 94.0 | |||||||||

| Tube Butt weld | 3/8 in | 57.2 | 28.4 | 25.4 | 31.8 | 38.1 | 34.0 | 94.0 | 94.0 | 7.9 | |||||||

| 1/2 in | 57.2 | 28.4 | 25.4 | 25.4 | 38.1 | 35.6 | 94.0 | 95.5 | 9.7 | ||||||||

| Pipe Butt weld | 1/4 in | 57.2 | 28.4 | 25.4 | 28.4 | 38.1 | 37.3 | 94.0 | 97.0 | 9.7 | |||||||

| Out VCO | 1/2 in | 57.2 | 28.4 | 94.0 | |||||||||||||

| Out VCR | 1/2 in | 79.2 | 39.6 | 38.9 | 15.7 | 98.6 | |||||||||||

| Orifice (11mm) | |||||||||||||||||

| Female NPT | 1/4 in | 79.2 | 39.6 | 33.3 | 39.6 | 50.8 | 46.2 | 50.8 | 15.7 | 17.5 | 88.9 | 26.2 | 121.0 | 126.0 | |||

| 3/8 in | 82.6 | 41.1 | 48.5 | 19.8 | 124.0 | ||||||||||||

| 1 in | 91.9 | 46.0 | 54.1 | 25.4 | 129.0 | ||||||||||||

| MNPT-FNPT | 1/4 in | 79.2 | 39.6 | 33.3 | 39.6 | 50.8 | 46.2 | 50.8 | 15.7 | 17.5 | 121.0 | 126.0 | |||||

| 3/8 in | 82.6 | 41.1 | 48.5 | 19.8 | 124.0 | ||||||||||||

| 1 in | 91.9 | 46.0 | 54.1 | 25.4 | 129.0 | ||||||||||||

| Tube Butt weld | 1/2 in | 99.6 | 49.8 | 42.7 | 52.8 | 60.2 | 46.2 | 47.8 | 15.7 | 17.5 | 121.0 | 123.0 | |||||

| 3/4 in | 104.0 | 49.8 | 42.7 | 52.8 | 60.2 | 46.2 | 47.8 | 15.7 | 17.5 | 121.0 | 123.0 | ||||||

| 1 in | 99.6 | 51.8 | 47.8 | 17.5 | 17.5 | 121.0 | 123.0 | ||||||||||

| 12mm | 99.6 | 49.8 | 42.7 | 52.8 | 60.2 | 46.2 | 47.8 | 15.7 | 17.5 | 121.0 | 123.0 | ||||||

| Tube Butt weld | 1/2 in | 79.2 | 39.6 | 33.3 | 42.9 | 50.8 | 46.2 | 47.8 | 15.7 | 17.5 | 121.0 | 123.0 | 9.7 | ||||

| 3/4 in | 79.2 | 39.6 | 46.2 | 15.7 | 121.0 | 11.2 | |||||||||||

| Pipe Butt weld | 1/2 in | 79.2 | 39.6 | 33.3 | 39.6 | 50.8 | 46.2 | 50.8 | 15.7 | 17.5 | 123.0 | 9.7 | |||||

| Out VCO | 3/4 in | 79.2 | 39.6 | 46.2 | 121.0 | ||||||||||||

| Out VCR | 1/2 in | 79.2 | 39.6 | 46.2 | 121.0 | ||||||||||||

Standards Of Needle Valve

Test & Inspection according to : API 6D / API 598

Design & Manufacture according to : BS 1868

Pressure & Temperature according to : ASME B16.34

Face to Face according to : ASME B16.10

Visual Inspection according to : MSS SP-55

Flange Dimensions according to : ASME B16.5

Marking according to : MSS SP-25

When to use needle valve?

This Valves used with higher differential pressure, and our valve standard range covers a pressure range up to PN40, and on request up to PN100. It can be manually actuated or can be controlled by electrical, hydraulic or pneumatic actuation.

Pressure-Temperature Ratings

| Material Name | 316SS | Alloy 400 | Alloy 20 | Alloy 600 | Alloy C-276 | Titanium | Material Name | 316SS | |||||||

|

Temperature 315°C(600 °F) |

Working pressure≤ ≥ 6000Psig(bar) | ≥ 10000Psig(bar) | |||||||||||||

|

–65 (–53) to 100 (37) |

6000(413) | 5000(344) | 5000(344) | 6000(413) | 6000(413) | 3570(245) | –65 (–53) to 100 (37) | 10000(689) | |||||||

| 200(93) | 5160(355) | 4400(303) | 4640(319) | 5600(385) | 6000(413) | 3110(214) | 200(93) | 9290(640) | |||||||

| 250(121) | 4910(338) | 4260(293) | 4500(310) | 5460(376) | 6000(413) | 2840(195) | 250(121) | 8840(609) | |||||||

| 300(148) | 4660(321) | 4120(283) | 4360(300) | 5320(366) | 6000(413) | 2570(177) | 300(148) | 8390(578) | |||||||

| 350(176) | 4470(307) | 4050(279) | 4185(288) | 5220(359) | 5975(411) | 2385(164) | 350(176) | 8045(554) | |||||||

| 400(204) | 4280(294) | 3980(274) | 4010(276) | 5120(352) | 5880(405) | 2200(151) | 400(204) | 7705(530) | |||||||

| 450(232) | 4130(284) | 3970(273) | 3955(272) | 5030(346) | 5710(393) | 2055(141) | 450(232) | 7435(512) | |||||||

| 500(260) | 3980(274) | 3960(272) | 3900(268) | 4940(340) | 5540(381) | 1885(129) | 500(260) | 7165(493) | |||||||

| 600(315) | 3760(259) | / | 3790(261) | 4780(329) | 5040(347) | 1625(111) | 600(315) | 6770(466) | |||||||

| 650(343) | 3700(254) | / | 3750(258) | 4700(323) | 4905(337) | / | 650(343) | 6660(458) | |||||||

| 700(371) | 3600(248) | / | 3710(255) | 4640(319) | 4730(325) | / | 700(371) | 6480(446) | |||||||

| 750(398) | 3520(242) | / | 3665(252) | 4430(305) | 4430(305) | / | 750(398) | 6335(436) | |||||||

| 800(426) | 3460(236) | / | 3600(248) | 4230(291) | 4230(291) | / | 800(426) | 6230(429) | |||||||

| 850(454) | 3380(232) | / | / | 4060(279) | 4060(279) | / | 850(454) | 6085(419) | |||||||

| 900(482) | 3280(225) | / | / | 3745(258) | 3745(258) | / | 900(482) | 5905(406) | |||||||

| 950(510) | 3220(221) | / | / | 2725(187) | 3220(221) | / | 950(510) | 5795(399) | |||||||

| 1000(537) | 3030(208) | / | / | 1800(124) | 3030(208) | / | 1000(537) | 5450(375) | |||||||

| 1050(565) | 3000(206) | / | / | 1155(79) | 3000(206) | / | 1050(565) | 5400(372) | |||||||

| 1100(593) | 2685(184) | / | / | 770(53) | 2685(184) | / | 1100(593) | 4835(333) | |||||||

| 1050(621) | 2285(157) | / | / | 565(39) | 2285(157) | / | 1050(621) | 4115(283) | |||||||

| 1200(648) | 1715(116) | / | / | 515(35) | 1545(106) | / | 1200(648) | 3085(212) | |||||||

Ratings are based on manual valves with optional Grafoil packing. Ratings are limited to:

200°F (93°C) max with PCTFE stem tip (NKR).

250°F (121°C) max with UHMWPE stem packing.

450°F (232°C) max with PTFE stem tip (NTR) or stem packing.

600°F (315°C) max with PEEK stem packing and 316 SS, 316/316L SSD, alloy 20, alloy 600, alloy C-276, or titanium

500°F (260°C) max with PEEK stem packing and alloy 400 (alloy 400 available in N series only).

1000°F (537°C) max with 316/316L SSD body, bonnet and stem components.

Testing of Needle Valve

Each set of HI-TEK threaded Needle Valve has been tested in the factory with nitrogen at 1000Psig (69bar), and the maximum allowable leakage rate of the valve is 0.1 standard cm³/m in. The shell test is based on the use of leak detection fluid, and there is no detectable leak.

Note: Packing may need to be adjusted during the service life of the valve. Valves that have not been opened for a period of time will have a higher initial force torque.